Product Focus: Rubberizing shoes and boots for the stage using 1812 (pictorial)

So, i don't feel like i can call this a tutorial, because this adhesive is fairly new to the theatre industry and definitely new to me. It was first recommended in the ACTS FACTS newsletter back in 2003 as a safer substitute for the carcinogenic solvent-based shoe-rubbering adhesive, Barge, by safety expert Monona Rossol. Ms. Rossol is reknowned for her work in furthering safety education among artists and craftspeople and is the author of many reference books on the subject, including The Health & Safety Guide For Film, TV, & Theater. Our company has recently acquired 5 gallons of the 1812, and i decided to test it out and see how it works!

1812 looks like a white glue--water-based, runny--but as it dries it goes through several phases, one of which is kind of slimy and weird like the floaty egg bits in egg drop soup, and finally ends up as firm rubber. I don't know where to tell you to purchase it easily--i know that we got it wholesale straight from the manufacturer, which is UPACO, a division of Worthen Industries. I predict that this will be one of those products that, like Foss Manufacturing's group of thermoformable plastics and felts, quickly becomes purchasable from retail businesses that cater to the entertainment industry, like Manhattan Wardrobe Supply and Backstage Hardware & Theatre Supply.

So, here's my "guinea pig" pair of boots:

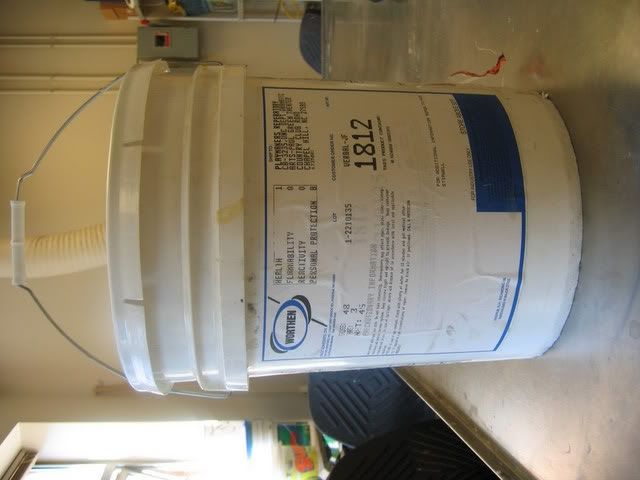

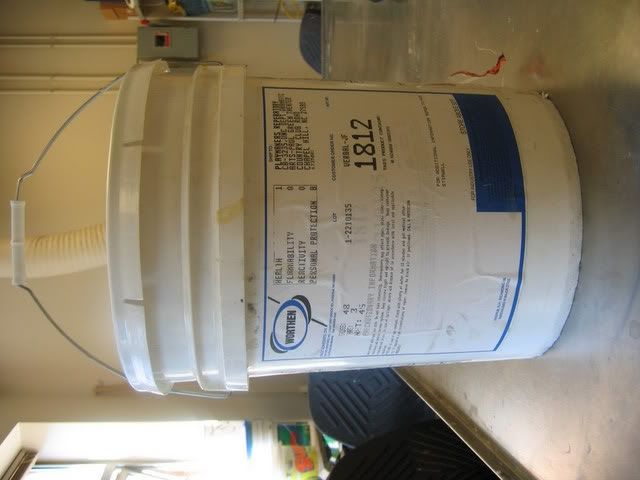

This is what my bucket of 1812 looks like.

The boots' uppers are vintage, but look at those brand new (slippery!) soles!

Our poor actress will bust it if she runs around onstage in these.

This shows you the difference between a roughed-up sole and a new sole.

The roughing gives the glue more texture to grab onto, so you get a stronger bond.

Trace your patterns like i described in my last post on rubbering with Barge.

Lay out your patterns on the rubber same as usual and cut out the pieces.

Here they are, while i wait for the two sides to dry enough that i can slap them together.

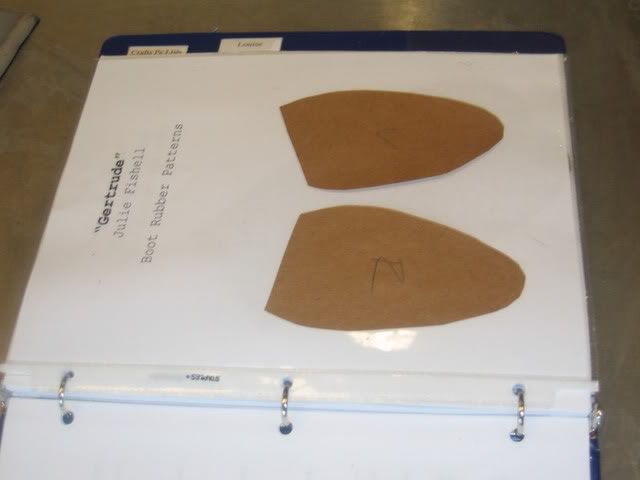

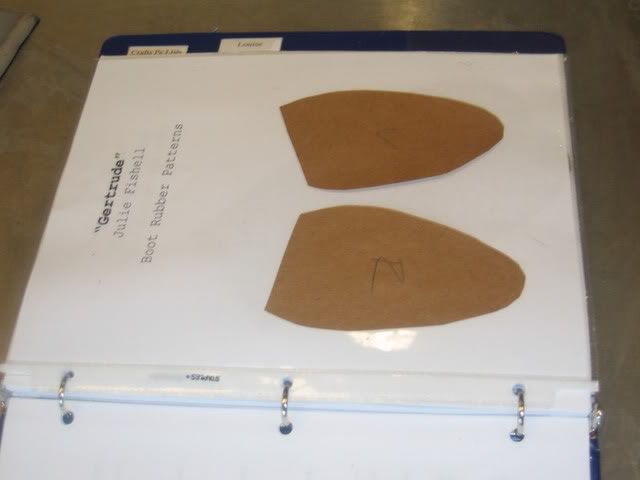

Incidentally, i label my patterns and keep them in my show bible in case i need to re-rubber the shoes.

Here you can see the boot on the iron. I tried putting the two together but they weren't to the right state of tackiness. Initially, it seems hard to judge the point at which the 1812 is no longer so runny it will peel right back off the surface, but not so rubbery-dried that the bond won't grab. It feels like this would be something that you'd get a feel for, the more frequently you worked with it.

Hammering isn't effective with 1812. I think that you hammer with Barge because Barge actually penetrates and dissolves the top layer of rubber, and the hammering squishes the runny rubber molecules up into the leather better. With 1812, it seems like clamping/clipping might be the best way to go? I guess more fooling with it will reveal whether that's true. The prospect of clamping every pair of shoes i have to rubber while the bond sets seems like way more of a pain than the Barge process, but that's a small price to pay for not having to suit up into some kind of haz-mat enclosure jumpsuit to use the stuff.

Of course, once the bond has set, you trim the edges just like normal, and send them off to rehearsal. I'll let you know if the rubber drops off before opening night!

1812 looks like a white glue--water-based, runny--but as it dries it goes through several phases, one of which is kind of slimy and weird like the floaty egg bits in egg drop soup, and finally ends up as firm rubber. I don't know where to tell you to purchase it easily--i know that we got it wholesale straight from the manufacturer, which is UPACO, a division of Worthen Industries. I predict that this will be one of those products that, like Foss Manufacturing's group of thermoformable plastics and felts, quickly becomes purchasable from retail businesses that cater to the entertainment industry, like Manhattan Wardrobe Supply and Backstage Hardware & Theatre Supply.

So, here's my "guinea pig" pair of boots:

This is what my bucket of 1812 looks like.

The boots' uppers are vintage, but look at those brand new (slippery!) soles!

Our poor actress will bust it if she runs around onstage in these.

This shows you the difference between a roughed-up sole and a new sole.

The roughing gives the glue more texture to grab onto, so you get a stronger bond.

Trace your patterns like i described in my last post on rubbering with Barge.

Lay out your patterns on the rubber same as usual and cut out the pieces.

Here they are, while i wait for the two sides to dry enough that i can slap them together.

Incidentally, i label my patterns and keep them in my show bible in case i need to re-rubber the shoes.

Here you can see the boot on the iron. I tried putting the two together but they weren't to the right state of tackiness. Initially, it seems hard to judge the point at which the 1812 is no longer so runny it will peel right back off the surface, but not so rubbery-dried that the bond won't grab. It feels like this would be something that you'd get a feel for, the more frequently you worked with it.

Hammering isn't effective with 1812. I think that you hammer with Barge because Barge actually penetrates and dissolves the top layer of rubber, and the hammering squishes the runny rubber molecules up into the leather better. With 1812, it seems like clamping/clipping might be the best way to go? I guess more fooling with it will reveal whether that's true. The prospect of clamping every pair of shoes i have to rubber while the bond sets seems like way more of a pain than the Barge process, but that's a small price to pay for not having to suit up into some kind of haz-mat enclosure jumpsuit to use the stuff.

Of course, once the bond has set, you trim the edges just like normal, and send them off to rehearsal. I'll let you know if the rubber drops off before opening night!