Silicon Valley Advanced Water Purification Center

Silicon Valley Advanced Water Purification Center

On Saturday D. and I took a brief tour of the Silicon Valley Advanced Water Purification Center, which process 8 million gallons of secondary-treated effluent a day and purifies it to a very high quality. Here are some of the pics I took.

The crowd waits for our tour to begin.

The intake area, with four 200-hp pumps to move the water through auto-strainers, screening out anything bigger than 300 microns before pumping it to the next phase.

A peek at the 2.25 million-gallon stainless steel tank which holds the final purified product, which will help augment the local water supply.

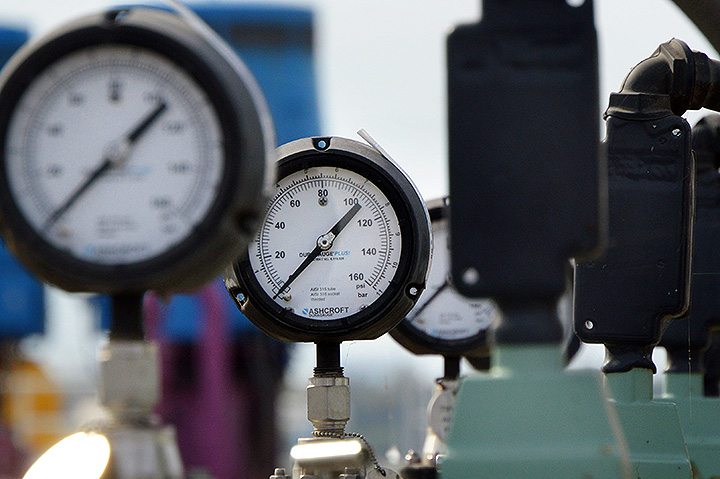

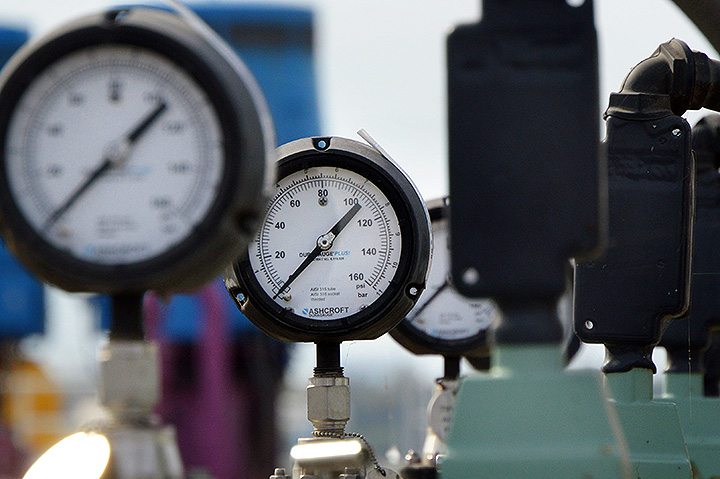

Gauges measure pressure in the intake system. They don't appear to be pumping anything at the moment.

One of the intake auto-strainers, which automatically backwash when the pressure differential gets too high.

Next we enter the Microfiltration-Reverse Osmosis-Ultraviolet Light Disinfection Process Building.

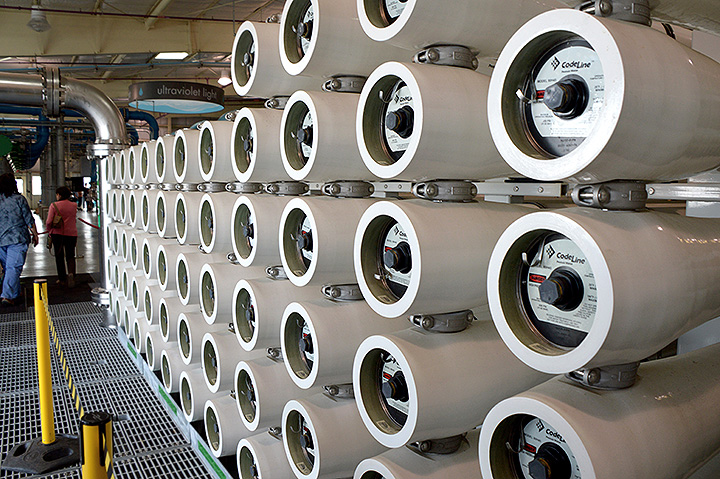

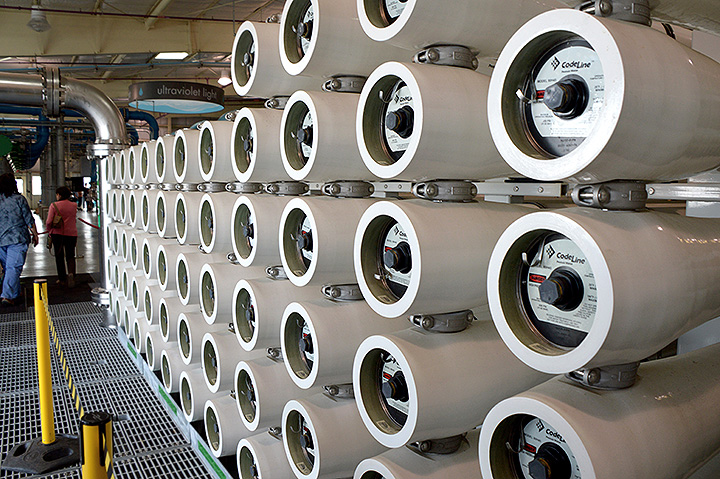

Ranks of microfiltration modules, each one packed with fibers that have pores about 1/300th the width of a human hair. If each strand of fiber were removed and laid end to end, it would span the entire length of California.

Water is drawn through the fibers' pores, filtering out solids, bacteria, protozoa and some viruses.

Next we see the 225,000-gallon inter-process tank and reverse osmosis transfer pumps. The water goes through 20-micron cartridge filters prior to reverse osmosis (RO membranes can be damaged by particles not filtered out).

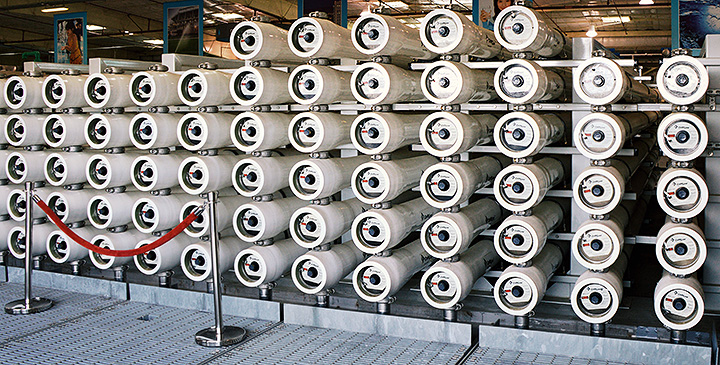

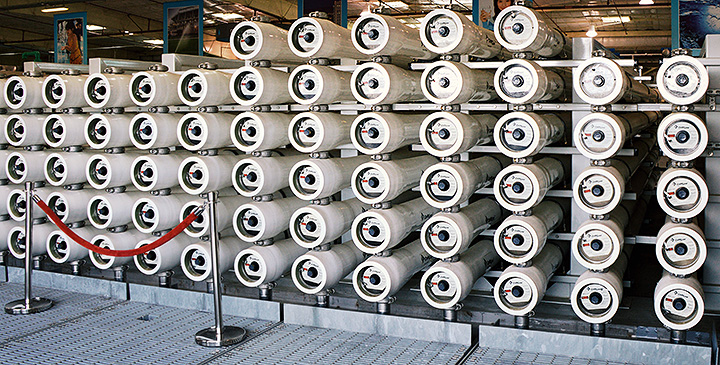

Here we see ranks of reverse osmosis modules. Three 500-hp pumps force the water through tightly-wound sheets of membranes with pores so small only a water molecule can pass through. This process removes contaminants, viruses, pesticides, salts and other materials from the water.

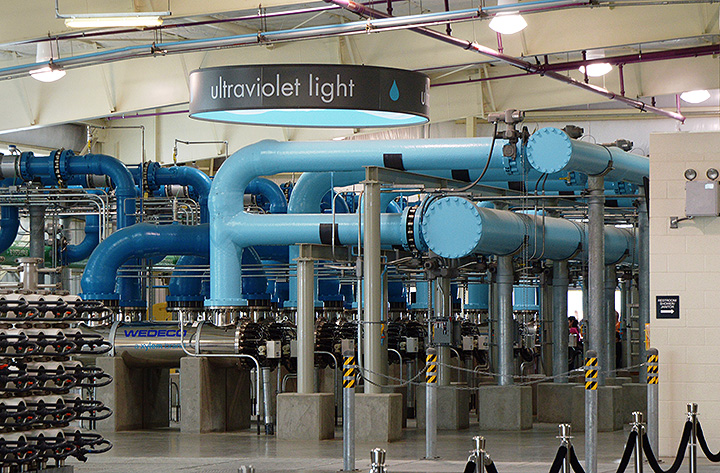

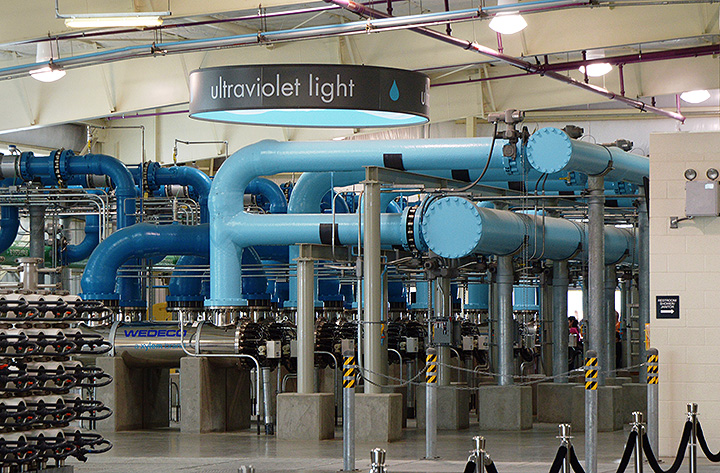

After passing through decarbonation towers, the next step is UV light disinfection.

Six vessels holding 40 high-intensity UV lamp bulbs further sterilize the water, breaking apart the DNA bonds of any virus or other pathogen that might have made it this far.

The water is now done being treated, and it goes to the 2.25 million-gallon product water storage tank, where it is blended with treated water from the Water Pollution Control Plant across the street to dilute the latter's high total dissolved solids. This plant's recycled water is cleaner than tap water. Blended water is used for landscaping irrigation, cooling towers, recharging groundwater, and many other industrial uses.

At the end of the tour we are provided a taste of the purified water, and although it is a little flat due to all the processing and filtering, it is bright and crisp.

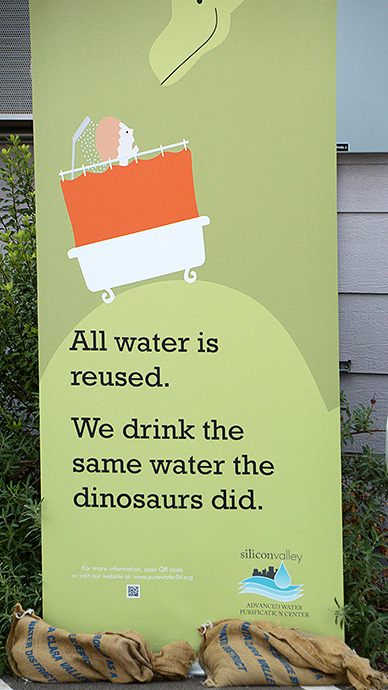

Wait a minute, all my life I've been drinking dinosaur pee?

One last look at the inter-process storage tank and a purple hydrant utilizing the plant's own purified water for fire fighting before heading home.

.

On Saturday D. and I took a brief tour of the Silicon Valley Advanced Water Purification Center, which process 8 million gallons of secondary-treated effluent a day and purifies it to a very high quality. Here are some of the pics I took.

The crowd waits for our tour to begin.

The intake area, with four 200-hp pumps to move the water through auto-strainers, screening out anything bigger than 300 microns before pumping it to the next phase.

A peek at the 2.25 million-gallon stainless steel tank which holds the final purified product, which will help augment the local water supply.

Gauges measure pressure in the intake system. They don't appear to be pumping anything at the moment.

One of the intake auto-strainers, which automatically backwash when the pressure differential gets too high.

Next we enter the Microfiltration-Reverse Osmosis-Ultraviolet Light Disinfection Process Building.

Ranks of microfiltration modules, each one packed with fibers that have pores about 1/300th the width of a human hair. If each strand of fiber were removed and laid end to end, it would span the entire length of California.

Water is drawn through the fibers' pores, filtering out solids, bacteria, protozoa and some viruses.

Next we see the 225,000-gallon inter-process tank and reverse osmosis transfer pumps. The water goes through 20-micron cartridge filters prior to reverse osmosis (RO membranes can be damaged by particles not filtered out).

Here we see ranks of reverse osmosis modules. Three 500-hp pumps force the water through tightly-wound sheets of membranes with pores so small only a water molecule can pass through. This process removes contaminants, viruses, pesticides, salts and other materials from the water.

After passing through decarbonation towers, the next step is UV light disinfection.

Six vessels holding 40 high-intensity UV lamp bulbs further sterilize the water, breaking apart the DNA bonds of any virus or other pathogen that might have made it this far.

The water is now done being treated, and it goes to the 2.25 million-gallon product water storage tank, where it is blended with treated water from the Water Pollution Control Plant across the street to dilute the latter's high total dissolved solids. This plant's recycled water is cleaner than tap water. Blended water is used for landscaping irrigation, cooling towers, recharging groundwater, and many other industrial uses.

At the end of the tour we are provided a taste of the purified water, and although it is a little flat due to all the processing and filtering, it is bright and crisp.

Wait a minute, all my life I've been drinking dinosaur pee?

One last look at the inter-process storage tank and a purple hydrant utilizing the plant's own purified water for fire fighting before heading home.

.